In the world of industrial electronics, the user interface is your product's handshake with the customer. At the heart of a robust and reliable HMI often lies a graphic LCD display module. These workhorses are ubiquitous, found everywhere from medical equipment and industrial controllers to automotive dashboards and test instruments. However, not all graphic LCD display modules are created equal. Selecting the right one requires a careful balance of performance, cost, and durability. This article breaks down the five critical factors to consider for your next project, with insights into how suppliers like Chuanhang Display engineer solutions for demanding environments.

Before diving into selection criteria, let's clarify the component itself. Unlike a character LCD that can only display predefined letters and numbers, a graphic LCD display module is a bitmap display capable of rendering arbitrary images, custom shapes, and complex user interfaces. It consists of a liquid crystal panel and a controller circuit. The "module" part is key—it means the display comes as a complete, ready-to-integrate unit, typically including the glass, driver ICs, a backlight, and a PCB with a standard interface (like SPI or 8-bit parallel). This turnkey nature significantly speeds up development time for engineers.

The datasheet is your first stop, but knowing what to look for is crucial.

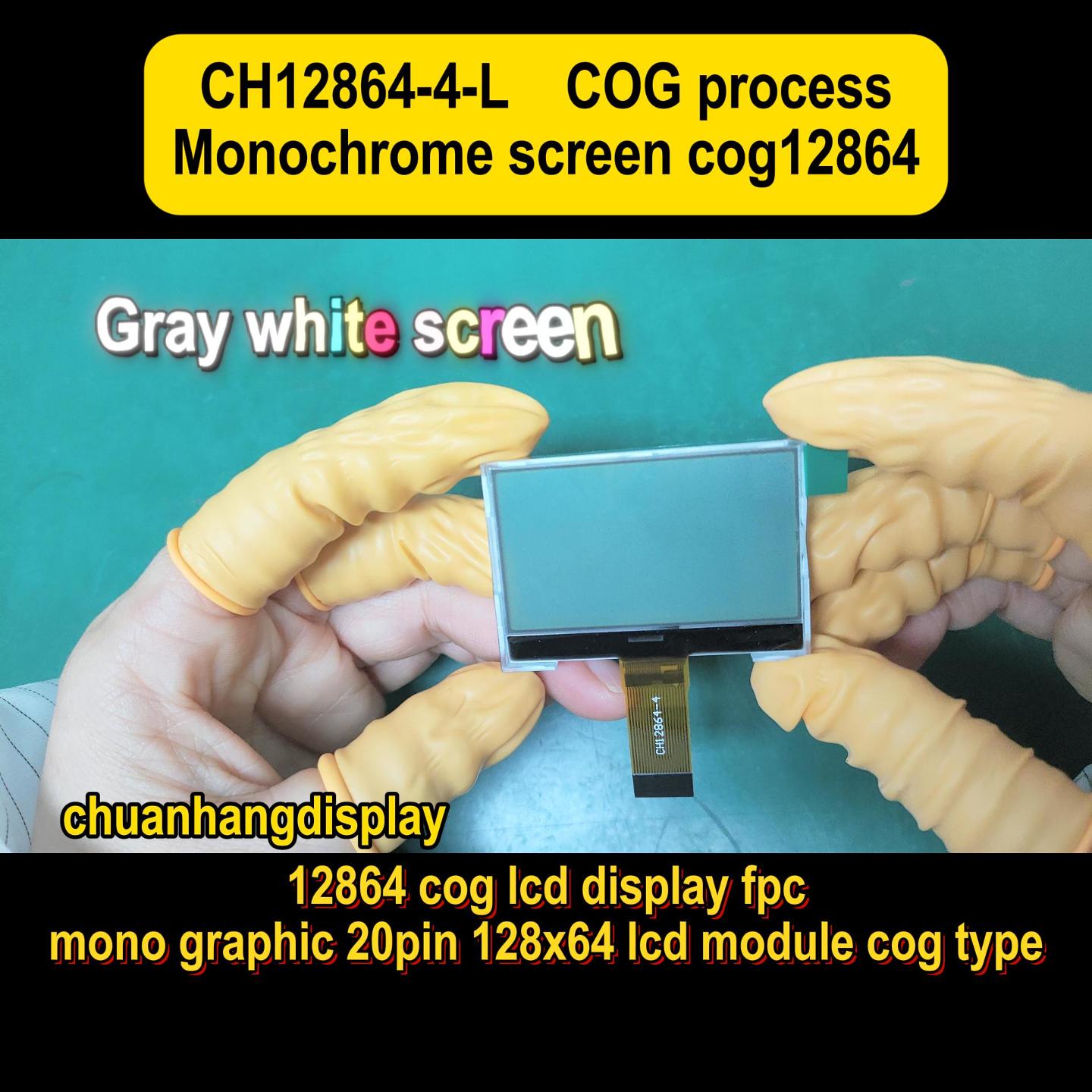

Resolution and Dot Pitch: This defines the clarity of your display. A 128x64 graphic LCD display module is a common standard, suitable for basic menus and data. For more detailed graphics, you might need 320x240 (QVGA) or higher. Remember, a higher resolution on the same physical size improves sharpness but may require a more powerful controller.

Viewing Mode (TN/STN/FSTN): This determines the visual appearance of the display without a backlight.

TN (Twisted Nematic): The most basic and cost-effective, offering a black-on-gray or white-on-blue appearance. Viewing angles are narrow.

STN (Super Twisted Nematic): Provides better contrast and wider viewing angles than TN, often seen as blue-on-white or black-on-gray.

FSTN (Film Compensated STN): A significant step up. It adds a compensation film to STN to create a high-contrast, black-on-white appearance, which is the standard for most modern, readable graphic LCD display modules.

Interface: The communication link between your microcontroller and the display. Parallel interfaces (8-bit/6800 series) are fast but use many GPIO pins. SPI is slower but highly pin-efficient, making it ideal for compact systems. Choosing the right interface is a fundamental system design decision.

Price is always a primary driver, but the true cost includes more than just the unit price.

Standard vs. Custom: Off-the-shelf modules are inexpensive and available immediately. However, if your design has unique size, shape, or performance constraints, a custom graphic LCD display module becomes necessary. While the NRE (Non-Recurring Engineering) costs are higher, a custom graphic LCD display can optimize the BOM, fit your enclosure perfectly, and provide a unique market advantage. Suppliers like Chuanhang Display often work with clients to manage this cost transition, offering semi-custom solutions based on existing platforms to keep costs down.

Total Cost of Ownership: Consider the longevity of the product. A slightly more expensive module from a reputable manufacturer with a guaranteed 10-year supply can be cheaper than redesigning your product in two years because a cheap module went end-of-life.

Industrial and automotive applications don't exist in a climate-controlled bubble.

Operating Temperature Range: A standard commercial graphic LCD display module might operate from 0°C to +50°C. Industrial-grade modules from Chuanhang Display are typically rated from -20°C to +70°C, and extended-temperature versions can handle -30°C to +80°C or beyond. This is non-negotiable for outdoor or harsh environment devices.

Backlight Lifetime: The backlight, usually LED-based, is often the first component to fail. A standard backlight might last 20,000 hours. For a device that runs 24/7, this is just over two years. High-reliability modules feature LEDs rated for 50,000 to 100,000 hours, ensuring the display outlives the product itself.

Sunlight Readability: This is a critical optical performance metric. A standard transmissive display washes out in direct sunlight. Solutions include high-brightness backlights (1000 nits or more), transflective displays that use ambient light to their advantage, or the use of polarized filters.

Your display supplier should be a partner. A company's capability directly impacts your project's success.

Engineering Support: Can they help you with interface issues, recommend the right controller, or assist with initial bring-up? This support is invaluable for accelerating time-to-market.

Supply Chain Stability: The recent global chip shortages highlighted the importance of a resilient supply chain. A manufacturer like Chuanhang Display, with vertical integration and strong relationships with IC foundries, can provide a stable, long-term supply of graphic LCD display modules.

Customization Capability: True customization goes beyond just the glass. It can include the cover lens (with optical bonding to reduce glare), the touch panel (resistive or capacitive), the connector type, and the firmware on the controller. Discussing these possibilities early in the design phase is key.

The modern graphic LCD display module is rarely just a display.

Integrating Touch: Resistive touch is a low-cost, proven solution that works with a stylus or glove. Projected Capacitive (PCAP) touch offers superior multi-touch experience but at a higher cost and sensitivity to environmental factors. The choice depends entirely on the end-user interaction.

The Rise of Intelligent Displays: To offload processing burden from the main system CPU, you can opt for an "intelligent" graphic LCD display module. These modules contain a more powerful internal controller (like an ARM Cortex-M core) that can handle the graphics rendering internally. Your main CPU simply sends high-level commands via UART or SPI, simplifying system design and freeing up valuable processing power.

Selecting the right graphic LCD display module is a multi-faceted decision that sits at the intersection of engineering, procurement, and product management. By rigorously evaluating technical specs, understanding the true cost of ownership, demanding the right environmental durability, partnering with a capable supplier like Chuanhang Display, and planning for advanced features like touch, you can ensure your product's interface is not just functional, but a durable and reliable asset.

Q1: What is the main difference between a character LCD and a graphic LCD display module?

A1: A character LCD is designed to display only a fixed set of alphanumeric characters and symbols. A graphic LCD display module, however, is a pixel-addressable bitmap display, meaning you can control every single pixel individually. This allows it to display any arbitrary image, custom font, graph, or complex icon, offering complete design freedom for the user interface.

Q2: My application will be used outdoors. What special considerations are needed for the graphic LCD display module?

A2: For outdoor use, you need to prioritize three things: a wide operating temperature range (typically -30°C to +80°C), high brightness (at least 800-1000 nits) for sunlight readability, and often an optical bonding process. Bonding the cover glass to the LCD eliminates an air gap, reducing internal reflection and condensation, which drastically improves performance in bright and humid environments.

Q3: Can I get a graphic LCD display module with a custom shape or cutout?

A3: Yes, this is a common custom graphic LCD display request. Suppliers like Chuanhang Display can produce modules with non-standard, irregular shapes, and specific cutouts to accommodate physical buttons, cameras, or sensors. Be aware that this requires a custom glass mask, which involves Non-Recurring Engineering (NRE) costs and a longer lead time for the initial production.

Q4: What is the typical lead time for a standard module versus a custom one?

A4: A standard off-the-shelf graphic LCD display module can often be shipped within 2-4 weeks. For a fully custom graphic LCD display module, the lead time is significantly longer. The process involves glass mask creation, sample approval, and production line setup, typically taking 8 to 14 weeks for the first batch, depending on the complexity.

Q5: How long does the backlight in these modules typically last, and can it be replaced?

A5: The LED backlight in a standard graphic LCD display module is typically rated for 50,000 hours (approximately 5.7 years of continuous use). In high-reliability modules, this can be extended to 100,000 hours. The backlight is an integral part of the module and is not designed to be user-replaceable. If backlight failure is a concern for your product's lifecycle, you should source a module with a higher-rated backlight from the outset.