Thermal analysis is vital for electronic device reliability. SINDA, or Systems Improved Numerical Differencing Analyzer, is a software tool used for simulating heat transfer. It helps engineers predict temperature distributions and prevent overheating. This article explores SINDA's role, with insights from Chuanhang Display, a leader in liquid crystal technology.

SINDA is a computational fluid dynamics software focused on thermal analysis. It models conduction, convection, and radiation in systems.

Developed by NASA in the 1960s, it has evolved for commercial use. Today, it is applied in aerospace, automotive, and electronics industries.

The tool uses numerical methods to solve heat equations. This allows for accurate simulations of complex thermal environments.

SINDA was created to address thermal challenges in space missions. Its early versions were used for spacecraft design.

Over time, it became more accessible. Modern updates include user-friendly interfaces and integration with CAD software.

Key milestones:

1960s: Initial development by NASA for aerospace applications.

1980s: Commercial release for broader engineering use.

2000s: Enhanced capabilities for electronics cooling simulations.

SINDA operates on finite difference or finite element methods. It divides systems into nodes for heat calculation.

Inputs include material properties and boundary conditions. Outputs provide temperature profiles over time.

This approach ensures reliable predictions. Engineers can optimize designs before physical prototyping.

SINDA simulates heat transfer by solving governing equations. Users define geometry, materials, and heat sources.

The software calculates temperature at each node. Results are visualized through graphs and reports.

This process helps identify hotspots. It also evaluates cooling solutions like heatsinks or fans.

SINDA offers features for precise thermal management. These include transient analysis and coupling with other tools.

Transient analysis: Models temperature changes over time.

Radiation modeling: Accounts for heat transfer in vacuums.

Fluid flow integration: Combines with CFD for convection studies.

These features make it versatile. Industries rely on it for critical design decisions.

The simulation starts with model creation. Geometry is imported or built within the software.

Next, thermal properties are assigned. Boundary conditions like ambient temperature are set.

Finally, the solver runs calculations. Engineers analyze results to improve system performance.

This iterative process saves time and costs. Chuanhang Display uses similar methods for display thermal design.

Liquid crystal displays (LCDs) face thermal challenges. Heat affects brightness, response time, and lifespan.

SINDA is used to model these effects. It helps design displays that operate reliably under various conditions.

Applications include consumer electronics and medical devices. Thermal management ensures consistent image quality.

LCDs generate heat from backlights and drivers. Excessive heat can cause:

Color shift: Changes in displayed colors.

Reduced lifespan: Faster degradation of liquid crystals.

Performance drops: Slower pixel response times.

Ambient temperature also impacts functionality. Displays in cars or outdoor settings need robust designs.

SINDA simulates heat flow in LCD modules. Engineers test different materials and layouts.

It predicts temperature rises in critical components. This guides the selection of cooling methods.

For example, simulations can optimize heatsink placement. They also assess thermal interface materials.

Chuanhang Display applies these insights. Their displays meet international standards for thermal performance.

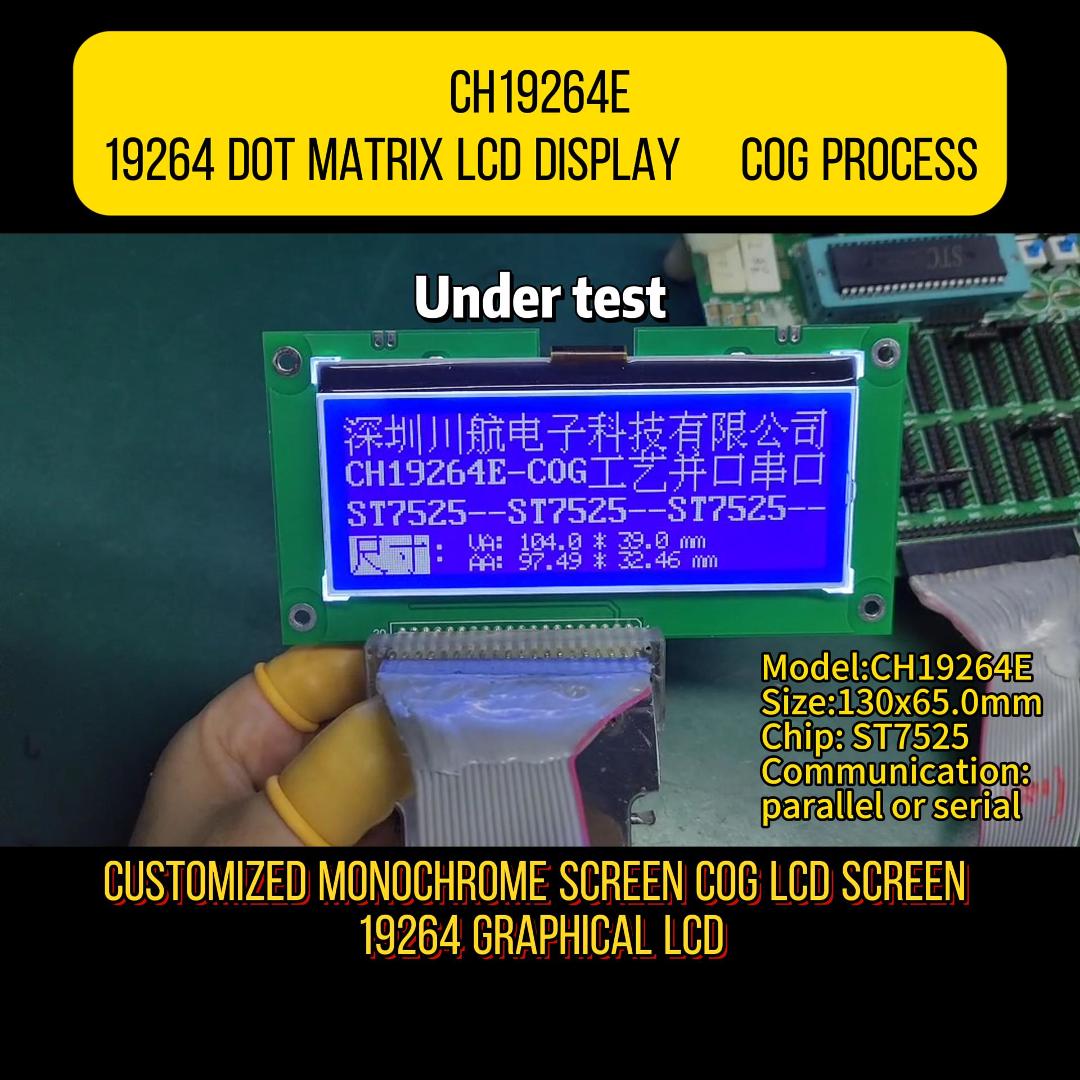

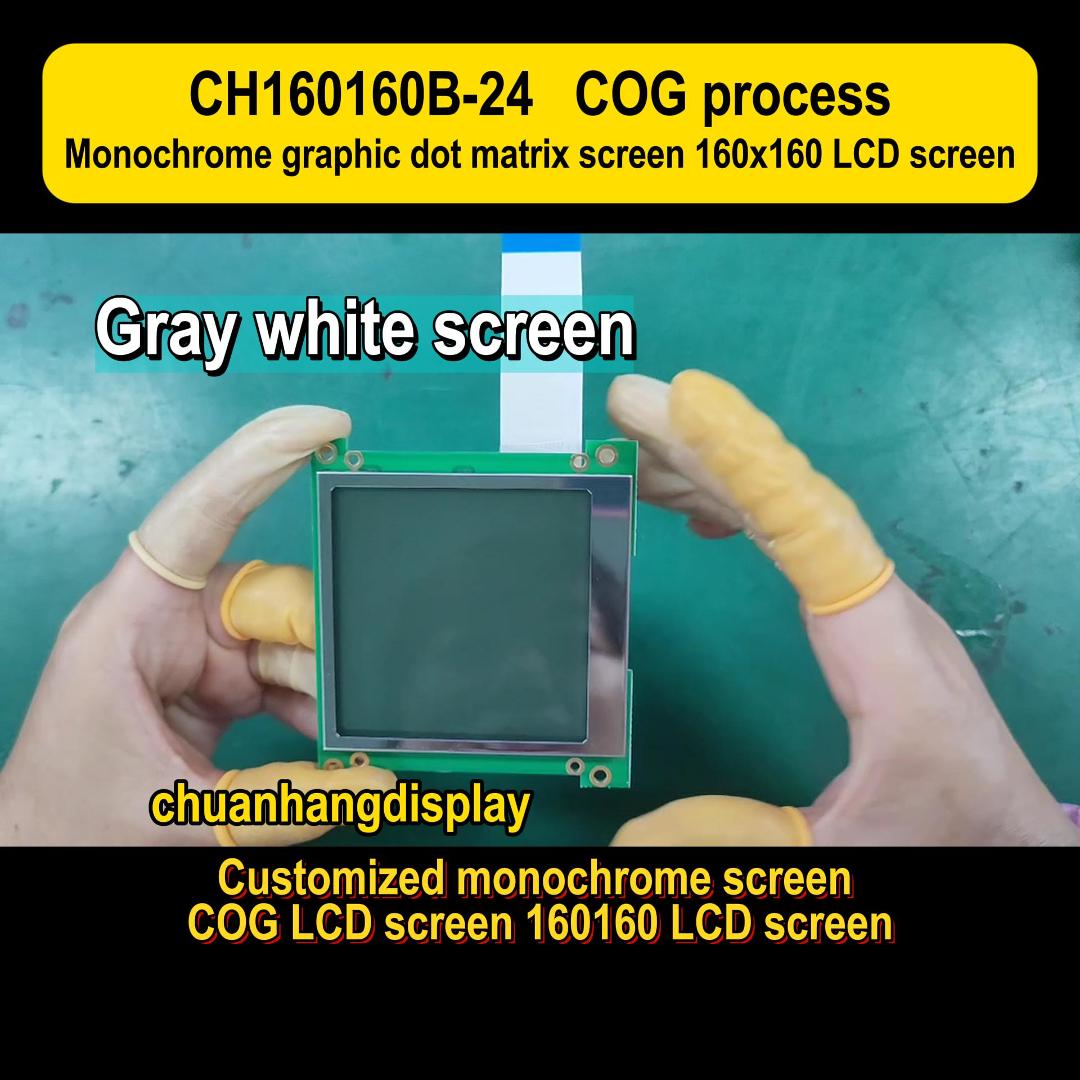

Chuanhang Display is a provider of liquid crystal displays. They integrate thermal analysis tools like SINDA into their processes.

This ensures products are reliable and efficient. The company serves global markets with customized solutions.

Their expertise covers industrial and consumer applications. Thermal management is a key focus area.

Chuanhang Display uses SINDA during product development. Simulations inform design choices early on.

This reduces the need for physical tests. It also speeds up time-to-market for new displays.

Key integration steps:

Modeling display assemblies in SINDA.

Analyzing thermal performance under load.

Iterating designs based on simulation results.

One project involved automotive displays. SINDA helped model heat from sunlight and electronics.

Solutions included enhanced ventilation and materials. The final product passed rigorous thermal tests.

Another case focused on medical monitors. Simulations ensured stable operation in warm environments.

These examples show practical benefits. Chuanhang Display leverages tools like SINDA for innovation.

Thermal analysis is evolving with technology. Advances in computing power enable more detailed simulations.

SINDA may incorporate AI for faster predictions. Integration with IoT for real-time monitoring is also possible.

In displays, trends include higher resolutions and flexible designs. These pose new thermal challenges.

Tools like SINDA will adapt to meet these needs. Chuanhang Display plans to stay at the forefront.

In summary, SINDA is a powerful tool for thermal analysis. It supports the design of reliable electronic devices, including liquid crystal displays. Companies like Chuanhang Display use it to deliver high-quality products. As technology advances, SINDA's role will remain crucial.

Q1: What does SINDA stand for?

A1: SINDA stands for Systems Improved Numerical Differencing Analyzer. It is software for thermal analysis and heat transfer simulation.

Q2: How is SINDA used in liquid crystal displays?

A2: SINDA models heat generation and dissipation in LCDs. It helps design displays that maintain performance under thermal stress, used by companies like Chuanhang Display.

Q3: What are the benefits of using SINDA?

A3: Benefits include accurate temperature predictions, reduced prototyping costs, and optimized cooling designs. It improves product reliability and development speed.

Q4: Can SINDA simulate other types of heat transfer?

A4: Yes, SINDA simulates conduction, convection, and radiation. It can handle complex scenarios like vacuum environments or fluid cooling systems.

Q5: How does Chuanhang Display incorporate SINDA?

A5: Chuanhang Display uses SINDA in the design phase to simulate thermal behavior. This ensures their displays meet industry standards and perform well in various conditions.